SUSTAINABILITY

Axium Packaging is committed to leading the industry in advancing the use of recycled materials, bioplastics and renewable energy for our customers, employees, communities and planet.

Advancing the Circular Economy

Axium leverages its experience, capabilities and entrepreneurial spirit to meet and exceed our customers’ sustainability goals. Our facilities are built to seamlessly transition between virgin and PCR on all equipment. We continually seek new ways to reduce landfill waste. We invest in next generation equipment and renewable energy initiatives to reduce our carbon footprint.

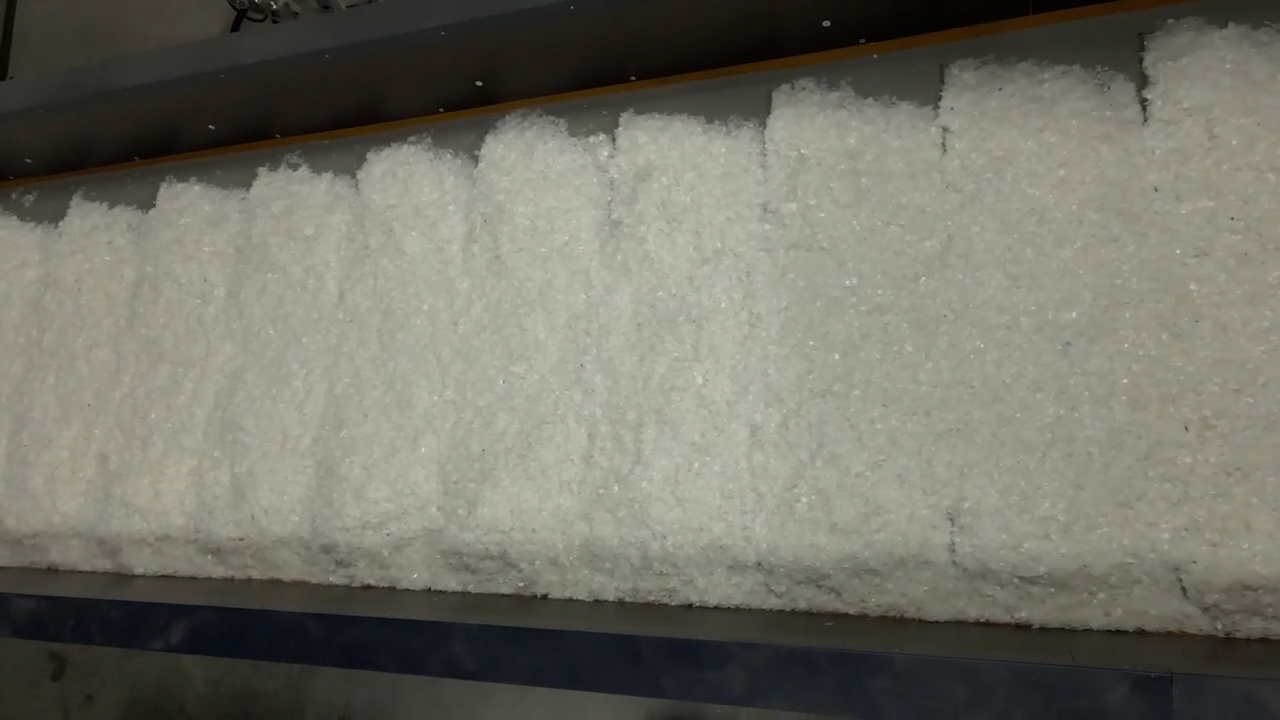

VERTIX RECYCLING FACILITY

Axium Packaging’s 120,000-square-foot, state-of-the-art recycling facility, Vertix, allows us to produce 50+ million pounds of post-consumer resin annually. We have invested significantly in high-grade sorting technology, continuous hot wash systems, and advanced filtration to produce a superior grade of material. Our process converts HDPE bales into FDA food-grade PCR. Partnerships with material recovery facilities ensure quality bales and a consistent natural, white, and mixed-color grade supply.

MATERIAL

ADVANCEMENTS

Our research and development team focuses heavily on advancements in plastic manufacturing to support our customers’ sustainability initiatives.:

- Filler Material for Light-Weighting

- Plant Based Resin

- Bi-Modal Grades

- PCR

- Liquid Colors

- High Concentrate Masterbatches

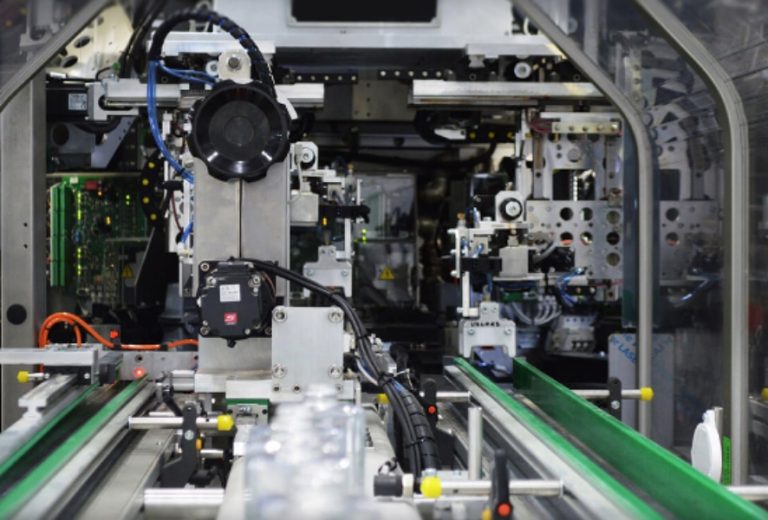

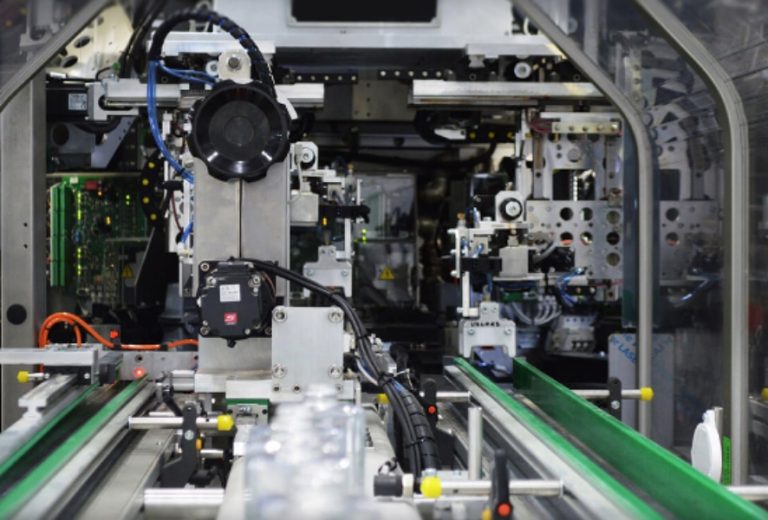

MACHINE PLATFORM FOR THE FUTURE

From electric machines to a closed loop system our platform is built around minimizing and eliminating waste throughout all steps of the molding process.

Our EBM technology is ideally suited to run either mono-layer with 100% PCR throughout the entire container, 6 layer barrier technology for extended shelf life or tri-layer capabilities to add PCR in the middle layer while keeping the inner layer virgin. Tri-layer also offers our customers significant savings when running expensive pearlescent colors by only running the colorant in the outer layer.

ECO-FRIENDLY TUBES

Our in-house tube and closure manufacturing facility simplifies the supply chain, cuts lead time from four to two weeks and reduces customers’ carbon footprint. High-speed extruders produce seven-layer tubes at a rate of 240 parts/minute. Eco-friendly tubes feature up to 100% PCR in monolayer tube sleeves and headers and up to 85% PCR with virgin inner and outer layers.

LIGHT WEIGHTING

Axium Packaging partners with our customers to reduce greenhouse gas emissions in multiple ways. Our light weighting initiatives have helped some of the world’s leading brands reduce their carbon footprint and meet sustainability goals by developing reusable bottles or simply minimizing the gram weight of existing bottles.

NEAR-SITE MANUFACTURING

Axium Packaging has a proven track record of rapidly scaling state-of-the-art, near-site manufacturing facilities for our customers. We can dramatically boost production capacity, expedite product launches and increase speed to market while reducing your carbon footprint.

FUTURE-READY FACILITIES

All Axium facilities are uniformly configured to run 100 percent PCR, 100% mixed-color PCR or 100% virgin on any of our manufacturing lines. We are one of the largest producers of EBM and ISBM bottles with up to 100 percent PCR in North America. Our plants achieve energy efficiency using a hybrid cooling system that flexes between electric and hydraulic, enabling us to use ambient cooling in the winter months with outside air to cool down recycled water.