DESIGN & INNOVATION

We are a collaborator who shares your vision for innovation, efficiency, quality and sustainability. We are driven to see not just what we can do, but how we can do it better, faster and smarter.

OUR PROCESS

From market research and brainstorming sessions to conceptual design, digital rendering and light-weighting, we constantly challenge the status quo to find new, more effective ways to not only meet our customers’ needs but exceed them.

DESIGN STUDIOS

Our ideation lab and in-house designers partner with you from concept to store shelf, enabling us to value engineer innovative packaging solutions that reduce costs, maximize efficiency and deliver a better consumer experience. We provide dedicated design teams that collaborate with our customers on new product launches, product makeovers, restaging and premiumization.

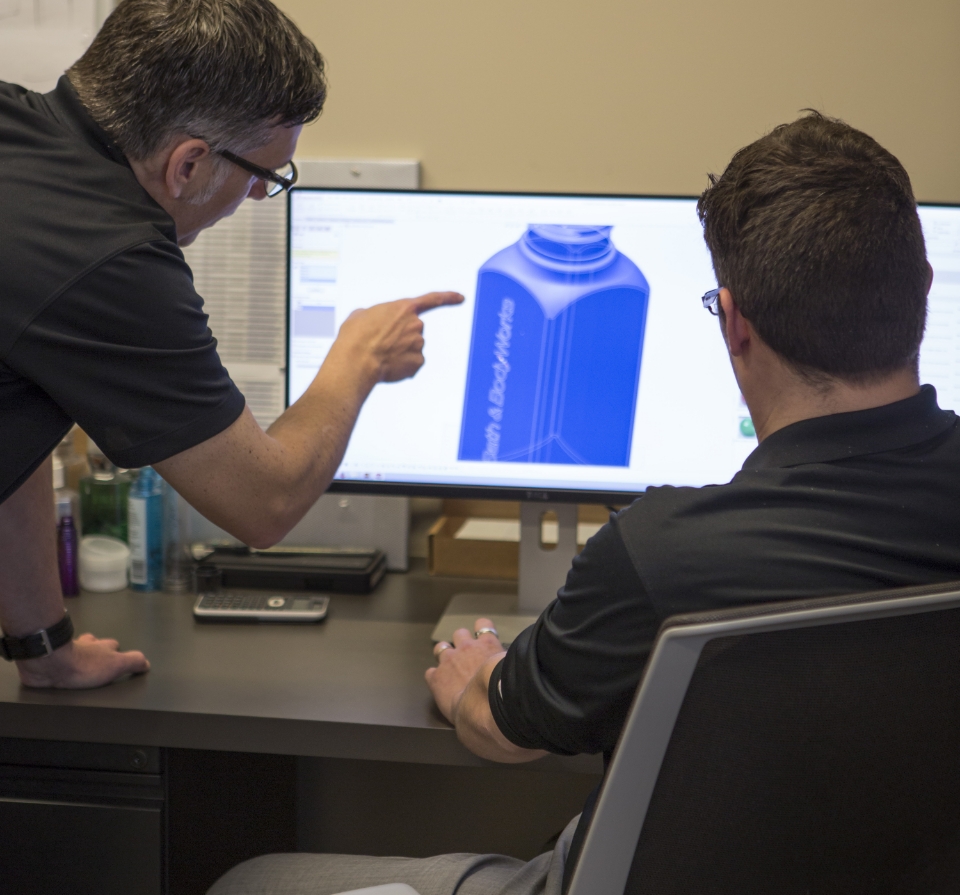

3D MODELING

Using advanced 3D modeling, Axium Packaging can create high-quality prototypes and packaging solutions that optimize brand appeal and can minimize material use. 3D modeling reduces BOTH the amount of time involved in prototyping and the need to repeat production of expensive molds.

MOLD SHOP

Built for innovation, speed, and agility, our in-house Mold shop allows Axium to design, build, qualify and commercialize tools in half the time and cost of our competitors. Our open-source model enables us to share 3D blow mold surface files to allow tooling to be developed concurrently around the world. With Axium’s mold development database we can often bypass unit cavities and go straight to production tools to reduce capital investment and expedite product launches.

NEAR-SITE MANUFACTURING

Axium Packaging has a proven track record of rapidly scaling state-of-the-art, near-site manufacturing facilities for our customers. Our near-site manufacturing solution can dramatically boost production capacity, reduce your carbon footprint and increase speed to market. In less than five months, Axium built and qualified 36 new tools and increased our production by more than 300 million units annually.

MARKETS SERVED

Our packaging solutions are unmatched in quality and diversity across various industries. We always strive for excellence, innovation, and accuracy in meeting the needs of our clients in different sectors.