EBM Technology

EXTRUSION BLOW MOLDING

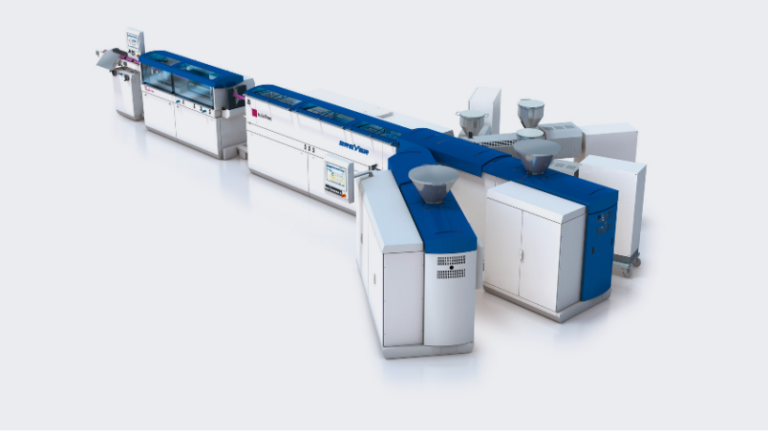

Facilities built with a common platform utilizing the latest technologically advanced shuttle machines available.

Capabilities

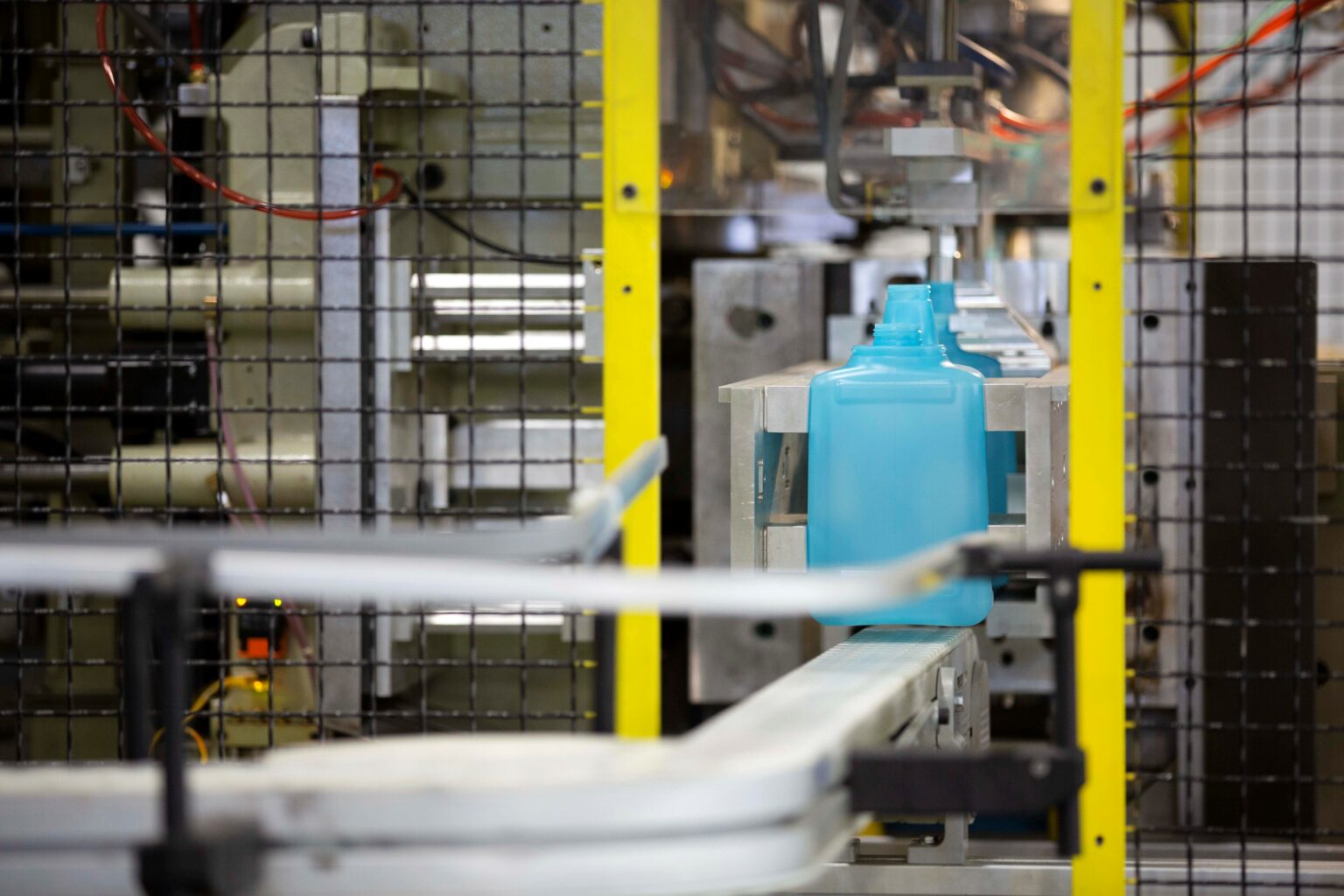

Axium produces bottles ranging in size from ½ ounce to 240 ounces. Our technology offers 100-point parison programming, providing the ability to consistently meet and hold tight tolerances by shifting material distribution as needed.

From monolayer to six-layer, Axium’s multi-layer capabilities allow our customers to use premium color pigments while reducing cost by coating only the outer layer of the bottle with premium pigment. For product stability, Axium utilizes an inner layer of virgin plastic and PCR throughout the rest of the bottle.

- High-Density Polyethylene – HDPE

- Low-Density Polyethylene – LDPE

- Polypropylene – PP

- Polyethylene Terephthalate Glycol – PETG

- Soft touch and various filler materials

- Up to 100% HDPE PCR (Post Consumer Resin)

- Monolayer

- Bi-Layer

- Tri-Layer

- Six layer with barrier capabilities

Markets Served

Personal Care

& Beauty

& Beauty

NEUTRACEUTICALS

HOUSEHOLD CHEMICAL

FOOD &

BEVERAGE

BEVERAGE

Healthcare

& OTC

& OTC

Molding your innovative vision into reality with precision.

EBM Advantages

- Quick and cost-effective unit and production tools

- Flexible platform

- Light weighting development with FEA software